Fuel Tank Safety Measures

Maybe you don’t give it much thought as you pass large fuel storage tanks, but if you live near them you might begin to wonder about their safety. That is especially true of anyone living in a concentrated area here on the westside. Sunoco, Clark and BP all have terminal facilities with numerous fuel tanks within a mile radius along Wilson Road and Fisher Road.

While Hollywood would have a field day portraying the huge explosions and disastrous annihilation that would result from these tanks exploding, the reality, according to fire experts and oil representatives is that there would not likely be anything tremendously dramatic about an accident at these containment sites.

Gerald Davis, media and public relations manager for Sunoco, Inc. said, "All tanks have some type of venting to prevent catastrophic failures as a result of over pressurization or vacuum.”

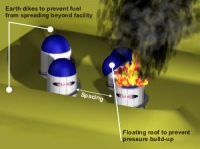

Some tanks are designed with weak roof-to-shell seams that burst, and some have floating or lifting roofs that completely when pressure builds. Pressure relief valves and pressure-vacuum vents are also common. Often, tanks have a combination of these safeguards, along with automated systems and manual checks to ensure that no tank is over filled.

Davis said that spacing is another crucial element in the safety of storage design. Davis said, "For the most part, the spacing standards used in the oil industry have required a greater degree of spacing than that required by the nationally used building codes. As a result, you will likely find a greater degree of separation around the tanks of an oil facility than in other heavy industries.”

Davis notes that the building codes would require two 100’ diameter gasoline tanks to be separated by only 33 feet. Sunoco’s current standard for new tanks of this size would recommend a separation of 150 feet.

Because of spacing, there would not likely be a chain reaction of fires should a tank ever catch on fire.

The next line of defense against the spread of fire is containment. The most common method of containment is to surround tanks with dike walls. When a tank gets too hot from burning fuel, its walls might melt and collapse, spilling out the fuel. The walls contain the fuel, and sometimes drainage paths escort the fluid to a "remote impounding basin.”

Because of the advance in technology and engineering, fire codes no longer require manual or fixed fire suppression on tanks that meet proper spacing and construction standards. Those compounds that require on-site fire responders would be oil refineries and chemical plants, not pipelines and terminal facilities.

Davis said, "Typically only those [fire] departments with a significant amount of storage tanks in their jurisdiction will be physically prepared for a storage tank fire.”

The west side storage tanks lie within Franklin Township. Franklin Township Fire Chief Fred Reedy said, "We feel we have the equipment and the foam to take care of a tank fire.”

Reedy noted that the difference between a tank fire and the normal fire that firefighters are accustomed to is the way they are approached. Firefighters are accustomed to running into a burning house without much pause for setup. A tank fire is different.

Said Reedy, "It’s not something you’re going to rush right in and take care of. It takes time to set up.” The primary weapon in this kind of fire is foam. Franklin Township has a truck that carries 1000 gallons of the foam.

The Columbus Metro Mutual Co-op is a group of oil companies in the area that meets once a month to discuss the condition of the fuel. Reedy said, "The purpose of that organization is safety.”

When asked how he feels about the departments readiness for an accident, Reedy said, "As comfortable as you can feel about something like that.”

Reedy shouldn’t feel too much worry. As he said, "The fire record is very safe.”

Sunoco would not speak about any specific accidents, but according to their 1999 Health, Environment and Safety Review and CERES Report, accidents were down. The report stated, "The 1999 OSHA recordable incident rate was 1.47, the lowest ever…” There were four fires for Sunoco in 1999, though they caused "no environmental or public health impacts.” All four fires were at refineries.

"As you can see,” said Davis, "we take the responsibility for safety very seriously.”

Originally published in the Westside Messenger

- Related Topics

Comment ignored.

SRI KANTH

Jul 27, 2010

Reply